Automatic Fish Scaling Station - Industrial/Commercial Grade

The Automatic Fish Scaling Station is a high speed fish scaler for commercial operations.

It has been produced for decades and is installed in many locations all over the world. It requires little maintenance other than periodic sharpening of the blades.

It can process up to 125 fish per minute. Larger fish take longer. Various models can handle fish from 4 oz. (113 g) to 16 lbs. (10 Kg.) and up to 12" wide. A video of various fish being processed in the scaler is available upon request.

Basic Automatic Fish Scaler Operation

The operator feeds the fish into the machine head first.

They are scaled by the machine and exit on the other side to a receptacle or conveyor (not included).

Water keeps the fish wet and washes the scales into the scale catcher.

PLEASE NOTE: The entire operation may cause damage to the head and fins, so it is recommended that fish are sold as headless fillets. NOT recommended if you sell fish whole.

More Information

The Automatic Fish Scaling Station can also be installed on fishing boats.

Eight models of the Trifisk Automatic Fish Scaling Station are available, each one tailored to a size, shape and type of fish. Call for pricing. We are competitive.

Model Selection Chart

| |

| | | |

Model | Fish that can be processed by machine | Weight | | Price |

|---|

| 4-C | Croaker, Dabs, Herring, Mullet, Ocean Perch, Pinchagua, Porgy, Small White Fish, Spot, Tilapia, Trout, Whiting | 4 oz - 4 lbs

113g - 1.8kg | | CALL TO DISCUSS

|

| |

| 4-CX | Blue Fish, Bream Cod, Croaker, Flounder, Haddock, Hake, Herring, Mullet, Ocean Perch, Pollock, Porgy, Red Snapper, Salmon, Spot, Tilapia, Trout, White Fish, Whiting | 8 oz - 9 lbs

170g - 4kg | | CALL TO DISCUSS |

| |

| 4-CXX | Cod, Croaker, Flounder, Haddock, Hake, Pollock, Red Snapper, Salmon, Spot, Trout, White Fish, Whiting | 1 lb - 18 lbs

1kg - 9kg | | CALL TO DISCUSS |

| |

| 6-C | Perch, Pike-Perch | 5 oz - 4 lbs

150g - 1.8kg | | CALL TO DISCUSS |

| |

| 6-CX |

Carp, Northern Pike, Pickerel, Pike-Perch, Salmon | 8 oz - 9 lbs

226g - 4kg | | CALL TO DISCUSS |

| |

| 6-HXX (one side) | Salmon, Red Snapper | 1 lb - 20 lbs

500g - 10kg | | CALL TO DISCUSS |

| |

| 10-CX | Custom Built; Pickerel (hard to scale) | 8 oz. - 9 lbs

226 g - 4kg | | CALL TO DISCUSS |

| |

| | | |

|

| | | | | |

Method of Operation - Automatic Fish Scaling Station

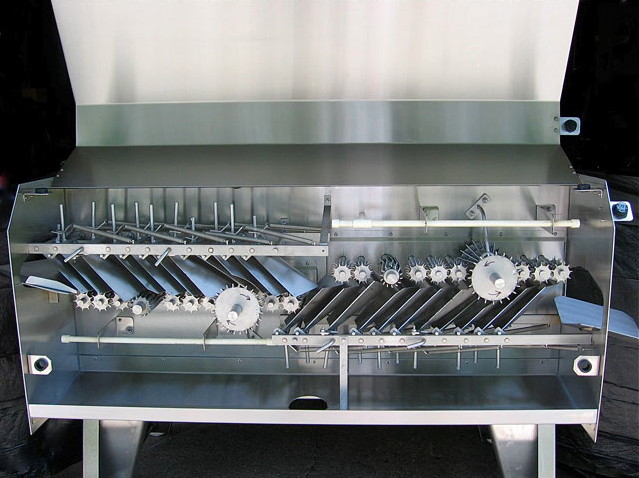

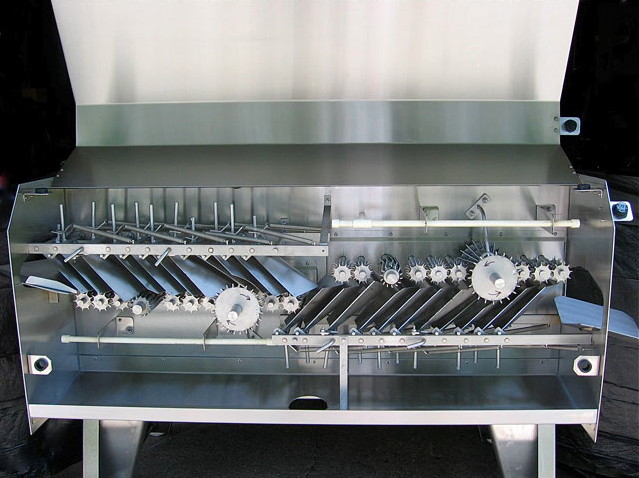

The machine is ready to operate upon delivery after being connected to proper electrical and water sources and a drain. The operator hand feeds each fish head-first into the entry chute. As the fish go through the machine from left to right, the fish are passed through a series of rollers and scaling heads.

Ordering and Delivery

The price is shown for each model. They are made to order and shipped to your location. You are responsible for uncrating and installation (electric, water, drain). Crating and other freight and delivery charges will apply.

Please call or email for a specific quote and discussion of your needs. The machine is built after a 50% deposit is received. The balance is due when the machine is ready to ship. Delivery time can vary from one to three months.

We ship internationally!

Questions? Call us!

Call us to with any questions about buying the Automatic Fish Scaling Station or to discuss your needs and the processing at your facility.

We will help choose the best electric fish scaling and pin-bone removing products for you. Ask for Ron.

- Finish: Commercial grade stainless steel cabinet and feeding table

- Water Supply: Automatically shuts valve when powered off

- Output: Up to 125 fish per minute (small sizes)

- Power Requirements: For different models: 208/220/380/440/550

- Water Requirements: 241 kPa (35 lbs pressure)

- Warranty: One Year limited warranty

- CE: Machine is CE compliant

MAINTENANCE INSTRUCTIONS

Before plugging your machine into a wall or ceiling outlet and especially after a relocation (NOTE THAT ELECTRICAL OUTLETS MAY HAVE DIFFERENT VOLTAGES), ensure that the voltage on the nameplate is the same as the line voltage. Contact a Certified Electrican if the line voltage is not the same.

You must remove the back cover to perform maintenance. Before you do that:

1. LOCK OFF THE MAIN POWER DISCONNECT SWITCH BEFORE REMOVING THE BACK COVER OF THE DE-SCALER.

2. Before removing the Back Cover, read and follow the instructions on the Warning Label on the cover.

3. PERFORM MAINTENANCE

- Lubrication should be made with light weight motor oil. All slow speed shafts require that the small oil cups of each Tri-bearing be topped off every six months under normal operating conditions.

- The Roller Chain, which drives all of the slow-speed shafts, can be lubricated with the same light weight motor oil, or sprayed with Chain Lube, every six months. Rotate the chains and sprockets by pulling down on one of the V-belts of the Infeed Bed Motor or the first Motor. Be careful not to get any of the oil or Chain Lube on the V Belts, because this will result in slippage.

Rotating the chains by pulling on one of the V Belts.

- All V-Belts are prone to wear, misalignment and stretching. After the first month of operation, check all V-Belts and tighten as required.

- Both the De-scaling Heads and the Drive Rollers will require re-sharpening after a few years, depending on the hours of operation. All the De-scaling Heads should be returned to the Factory for re-sharpening. Please notify us before sending them.

| Click the picture to start the video. | |

| | |

|  | |